Download a PDF version of this page

Understanding the creation, effects, and how to reduce common mode over voltage

What is Common Mode?

To start off, common mode is bad. Common mode voltage is created by Variable Frequency Drives (VFDs) that serve as a way of controlling the speed of AC motors by varying the frequency of the power source using pulse width modulation (PWM). This is done by switching the transistors, IGBTs, or thyristors, on and off continuously.

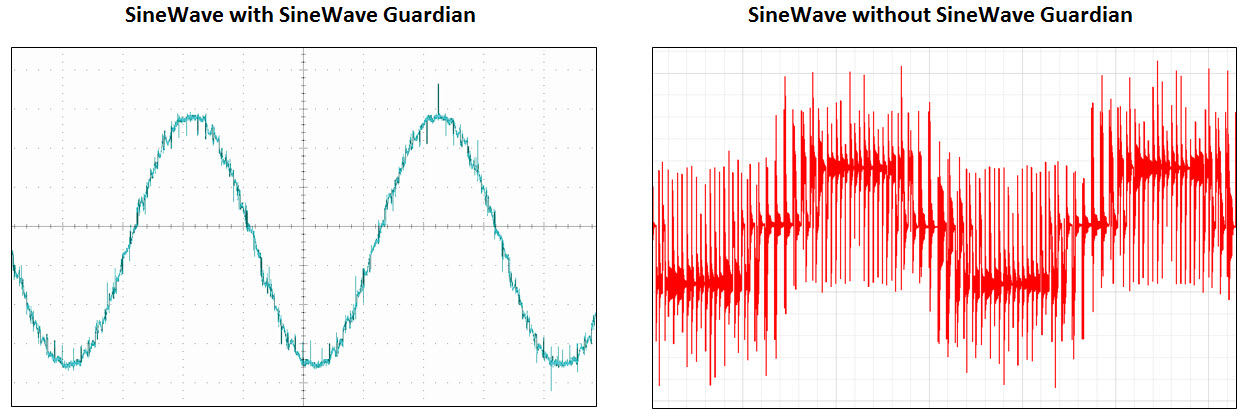

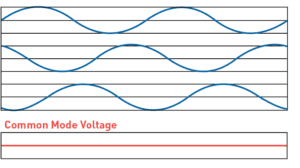

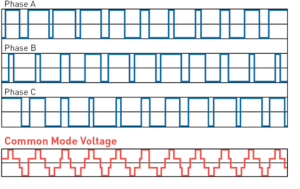

The continuous generation of power pulses from VFDs prevents a smooth sinewave from being produced, which at any point is at a sum of zero (see Fig.1). Instead, the waveforms produced result in a sum at any point that is not always zero (see Fig.2). The result is damaging common mode over voltage, which can cause devastating effects to your equipment.

Fig.1

Fig.1

Three Phase Utility Power produces three smooth sinusoidal

waves which at any point average a sum of zero. This creates an

optimal scenario with zero common mode over voltage.

Fig.2

Fig.2

Power produced by VFDs is given off in continuous generation of pulses,

which on average achieve a sinewave. However, the sum at any point is

not always zero, resulting in damaging common mode over voltage.

Destructive Effects of Common Mode Over Voltage

Common mode problems occur outside of the VFD, which is why they are difficult to diagnose. The effects of common mode over voltage are extremely problematic for everyday operations. These problems negatively effect your bottom line, creating the need to replace equipment, increase repair costs, and can result in the loss of production.

How Do I Eliminate Common Mode Over Voltage?

Unfortunately, common mode over voltage cannot be eliminated, but it can be reduced. There are a few solutions to combat common mode over voltage: a properly designed dV/dt filter, common mode choke, or a shaft grounding kit to protect motor bearings. But, each of these is not created equally, and there is only one solution that stands above them all – the patented Triple Core Defense of the dV Sentry™.

________________________________________________________________________________________________________________________________________________________

Common mode problems include:

• Damage to motor bearings

• Unexpected ground fault trips

• Erratic behavior of VFDs and PLCs

• Premature motor insulation failure

• Cable damage

________________________________________________________________________________________________________________________________________________________

Solutions for Common Mode Reduction:

the dV Sentry & SineWave Guardian

The dV Sentry™ is the only proven filter to provide common mode reduction, peak voltage protection, and rise time reduction – all in one unit.

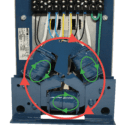

The dV Sentry’s Unique Patented Triple Defense Core

The dV Sentry’s Unique Patented Triple Defense Core

The patented design of the dV Sentry™ and its Triple Defense Core are like nothing you’ve seen before.

- Common mode reduction: Filters power through the outer core and reduces common mode current.

- Peak voltage protection and rise time protection: Power filters through inner core, reduces rise time, and gives peak voltage protection.

dV Sentry vs. the Rest

The dV Sentry outperforms the competition with proven results. Of the three filters tested, a typical dV/dt filter, a common mode choke, and the dV Sentry filter, the dV Sentry showed that it was a standout among the competition. Each filter was tested using a 480V, 50 hp drive system with 1,000 feet of cable, 8 kHz switching frequency, and at full load. While many of the competitors claim to reduce common mode voltage, they fail to back it up.

| Filtering | Filter Common Mode Dampening | Change in Common Mode Current | Note |

|---|---|---|---|

| Typical dV/dt Filter | N/A | -5% | Negligible Common Mode Filtering |

| Common Mode Choke | None | 18% | Unreliable Common Mode Filtering |

| Shaft Grounding Brush | N/A | 0% | Can Protect Bearings |

| MTE dV Sentry Filter | Optimal | -47% | Reliable Common Mode Filtering |

The SineWave Guardian: For motor protection, there is nothing better.

Motor protection and power quality don’t have to be a mystery. MTE makes it easy. Case in point: our SineWave Guardian™ Filter. This best-in-class filter delivers unequaled performance in cleaning the PWM waveforms generated by Variable Frequency Drives (VFDs). It virtually eliminates high frequency content and voltage peaks, thereby reducing motor heating to give you extended motor life – and less downtime. The SineWave Guardian also offers incredible reliability and durability. It is more efficient and tolerates higher ambient temperatures, making it ideal for a variety of applications from steel mills to oil fields. Its modular design and smaller footprint make it easier to integrate and install. It all adds up to the best SineWave Filter, and the best value on the market today.

Motor protection and power quality don’t have to be a mystery. MTE makes it easy. Case in point: our SineWave Guardian™ Filter. This best-in-class filter delivers unequaled performance in cleaning the PWM waveforms generated by Variable Frequency Drives (VFDs). It virtually eliminates high frequency content and voltage peaks, thereby reducing motor heating to give you extended motor life – and less downtime. The SineWave Guardian also offers incredible reliability and durability. It is more efficient and tolerates higher ambient temperatures, making it ideal for a variety of applications from steel mills to oil fields. Its modular design and smaller footprint make it easier to integrate and install. It all adds up to the best SineWave Filter, and the best value on the market today.

SineWave Guardian Performance:

The SineWave Guardian is a SineWave Filter which protects motors from damage by “cleaning” the sinewave waveform that is generated by the Variable Frequency Drive.

Want to learn more?

- White paper for detailed specifications about Common Mode and its effects

- dV Sentry video

- More power quality solutions from MTE

Did You Know: Your system could experience peak voltages and rise times that exceed the NEMA MG-1, Part 31 Standard for inverter duty motors.